ID card printers are different from desktop inkjet printers because they use colored ribbons instead of ink to print on plastic cards. These ribbons contain sets of color panels which are either multicolored or monochrome. Each panel is slightly larger than an ID card, and for each color used in a card design the printhead will make a pass over the corresponding ribbon panel.

There are two main methods of ID card printing—dye sublimation and reverse transfer. Both methods use colored or monochrome ribbons, but the type of printer you need depends on the preferences of your organization.

Dye Sublimation ID Printers

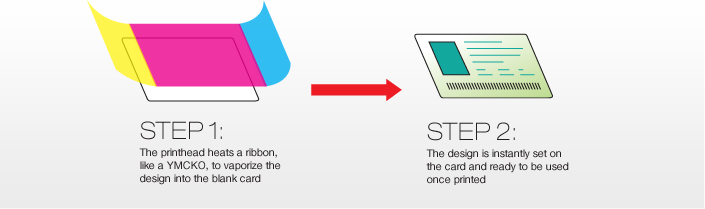

Most ID card printers use dye sublimation, which is also known as direct-to-card printing. Dye sublimation is the process where the printhead heats the printer ribbon and the ink vaporizes and bonds with the plastic card. This type of printing produces average quality cards at higher print speeds. Dye sublimation printers feature edge-to-edge printing, but the edge itself can be seen as a very thin white line.

Dye sublimation is the standard method of printing ID cards and is more economical than reverse transfer printing. Since themajority of ID card printers use this method, it gives you more options and flexibility when selecting an ID card printer.

View All Dye Sublimation Printers

Dye Sublimation Benefits:

- More Economical

- Wider Variety of Printing Options

- Faster Print Speeds

- Average Quality

Reverse Transfer ID Printers

Reverse transfer printing, also known as retransfer printing, is a higher-end technology that produces crisp, high definition cards. Like dye sublimation, this method also uses a heated printhead and ribbon, but adds an additional step with a clear film. The card’s design is first printed on the clear film, and that film is then fused onto the card. This extra step results in slower print speeds than dye sublimation printing, but offers better visual print quality and allows for true over-the-edge printing since the clear film is larger than the card.

By printing on the film first, reverse transfer ID cards are more durable and resistant to tampering. Reverse transfer printing is also the best choice for printing on technology and smart cards, since the printhead never comes into contact with the uneven card surface, which can damage the printhead of a dye sublimation printer.

Reverse transfer printers are more expensive than dye sublimation printers, and the supply cost per card is also higher due to the extra film that is used in the printing process. This type of printer is ideal for organizations which have higher than average graphic standards, need extra durable cards, or need to print on technology cards.

View All Reverse Transfer Printers

Reverse Transfer Benifts:

- Highest Definition

- True Over-the-Edge Printing

- Longer-Lasting ID Cards

- Ideal for Technology & Smart Cards